Hydrogen has recently become widespread as a sustainable carrier for fuel and other substances in various industries, including aerospace, automotive, and energy sectors. However, the significant risk of hydrogen embrittlement in metal structures poses a challenge, as the effects can be devastating, often leading to severe accidents and costly repairs of critical components.

1. What is Hydrogen Embrittlement?

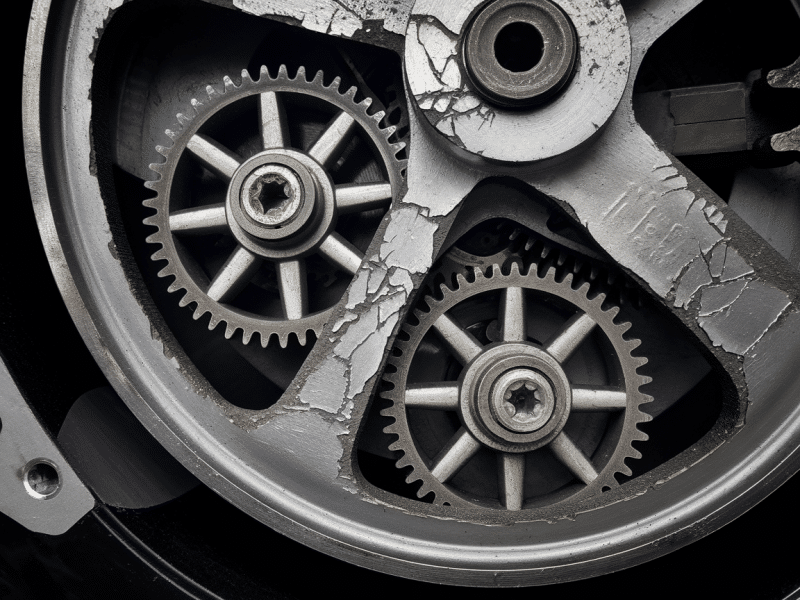

Hydrogen embrittlement will cause certain metals to become brittle and susceptible to fracture. Signs of this phenomenon include altered surface texture or appearance and visible cracks or fractures on high-stress areas of the metal components. This could result in sudden and catastrophic failures of critical components, posing safety hazards to the on-site equipment and operating personnel.

The causes and effects of hydrogen embrittlement are highly intricate, involving alterations in the metal’s microstructure, the penetration of hydrogen atoms, and their interactions with stress. We will explore the common causes of hydrogen embrittlement in subsequent sections.

2. What are the Causes of Hydrogen Embrittlement?

A combination of factors, including corrosion, electrochemical reactions, and mechanical stresses can trigger hydrogen embrittlement.

2.1. Corrosion

Corrosion is one of the most influential factors that cause hydrogen embrittlement. The different types of corrosion that could lead to the diffusion of hydrogen into the metal include:

- Galvanic Corrosion: Occurs when two dissimilar metals are in contact in a corrosive environment, generating hydrogen gas that is absorbed by the metal.

- Pitting Corrosion: Creates localized pits or holes that serve as initiation sites for hydrogen absorption.

- Crevice Corrosion: Common in confined spaces, this type of corrosion can facilitate hydrogen generation and absorption due to the aggressive local chemistry.

2.2. Electrochemical Reactions

Certain manufacturing processes may cause electrochemical reactions that further contribute to the phenomenon of hydrogen embrittlement. For instance, electroplating and cathodic protection can involve the application of electrical currents, leading to hydrogen evolution and subsequent absorption. Additionally, high-temperature processes like welding and casting may also lead to hydrogen dissolution in the metal matrix as it cools.

2.3. Mechanical Stress

Mechanical stresses can create pathways for hydrogen absorption. When metals are subjected to mechanical loads, they can develop dislocations and microcracks. These defects can serve as entry points for hydrogen atoms and cause them to diffuse into the metal’s microstructure, leading to hydrogen embrittlement.

3. Ensuring Structural Integrity with Reliable, High-Quality Fasteners

To combat hydrogen embrittlement, using reliable, high-quality fasteners is essential. A trusted fasteners ‘ provider ensures durability and resistance to environmental, chemical, and mechanical challenges, safeguarding the integrity of your projects.

Known for high-quality, ISO-certified, and RoHS-compliant solutions, Fivetech provides fasteners that meet specific industry needs. To ensure structural integrity and safety, we implement a strict dehydrogenation process for high-strength steel parts treated with mechanical plating, adhering to ISO 15330 standards. Additionally, our in-house hydrogen embrittlement testing complies with international guidelines like JIS B1045 and ISO 15330, guaranteeing that plated screws pass stringent tests without fractures, ensuring reliability in demanding environments.

With quick delivery, customizable options, and a stable production scale, Fivetech helps clients minimize downtime and enhance operational efficiency. Ready to experience the reliability and convenience of quick-release fasteners? Check out our comprehensive catalog or contact us today for a custom solution!

Browse Fivetech’s Reliable Quick-Release Fastener Solutions

You May Also Be Interested In:

➤ Fivetech Quick Release Fastener | All Solutions

➤ Fivetech’s Captive Screws and Fasteners

➤ Ultimate Guide to Captive Screws: Types & Applications

➤ How to Measure Screws, Bolts, and Threads Sizes – Fivetech

➤ Quarter Turn Fastener – Fivetech

➤ A Guide to Folding Handles: Embracing Compactness and Functionality

➤ Fivetech’s Thumb Screws: Convenient and Reliable

➤ Understanding Server Hardware & Its Main Components – Fivetech